Computer-to-Screen Printers

Drive Productivity

EXILE Technologies offers a number of direct-to-screen printer solutions to assist you in driving productivity in your screen production area. Our industry-leading products include the Spyder X, SCREENMAKER, and our LED CTS Exposure Units, The Expose CTS and V-Lux.

Many textile screen printers today are well aware of the advantages of adding a computer-to-screen imaging system into their pre-press workflow. CTS imaging eliminates film, reduces labor and overhead costs, and does so in a fraction of the time it takes to accomplish the same effort traditionally. A direct-to-screen printer can also provide an immediate quality improvement if it replaces an inkjet or toner-based film workflow.

CTS Products

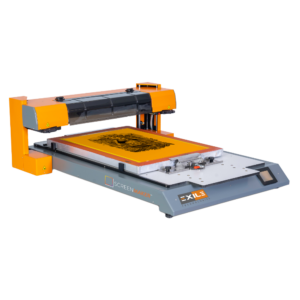

Spyder X

The SPYDER X is EXILE Technologies’ most advanced Computer-to-Screen printer, designed to push the boundaries of speed, precision, and versatility. Equipped with cutting-edge imaging technology, it delivers ultra-high-resolution stencils with unmatched detail and clarity. Ideal for large-scale production, the SPYDER X maximizes efficiency while maintaining superior quality, making it the ultimate CTS solution for screen printers aiming to stay ahead in a competitive industry.

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Benefits

- Bi-Directional Printing

- Improved Interlacing

- Eliminates Film

- Reduced Labor Costs

- Precision Placement

- Faster Press Setup

- Improved Quality

- Reduced Exposure Times

Equipment Specifications

- Model: SPYDER X Computer-to-Screen system

- Technology: Phase-change inkjet/Solid ink

- Resolution: 600 dpi

- Halftone Capability: 70 lpi @ 600 dpi

- Imaging Speed: Approximately 2.4 sq ft/min (13 sq m/h) @ 600 dpi

- Accuracy: .001” from screen to screen

- Power Requirements: 120v/220v 50-60 HZ 15 amp

- Compressed Air: Required

- Network: Ethernet

- Operating Temperature: 50ºF to 86ºF/10ºC to 30ºC

- Operating Humidity: 35% to 75% non-condensing

- Ink Type: Solid block/Water dispersible photoresist mask

- Max Media Size: 30 x 40, (30 x 43 with optional adapter)

- Max Image Size: 24 x 29

- Dimensions: 36 x 52 x 74 (79 cm x 124 cm x 155 cm)

- Weight: 300 lbs (136 kg)

RIP Specifications

- RIP Type: Harlequin

- RIP Platform: Windows

- Screening: AM and FM (Stochastic) Screening Available

- Input File Formats: Postscript III, PDF, EPS, TIFF

- RIP Options: Auto Trapping, Color

- Management/Proofing, Hybrid Screening

SPYDER II

The SPYDER II is a trusted industry standard in Computer-to-Screen (CTS) technology, offering precise, high-resolution imaging with a seamless workflow. Designed for efficiency, it eliminates the need for film positives by directly jetting images onto emulsion-coated screens, reducing setup time and material costs. With its reliable performance and sharp detail reproduction, the SPYDER II is a go-to solution for screen-printing shops looking to enhance productivity without compromising quality.

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Benefits

- Bi-Directional Printing for Faster Output

- Reduces Screen Room Labor

- Supports Frame Sizes up to 46” x 55”

- Better Density than Most Film and Liquid Ink CTS Systems

Equipment Specifications

- Model: SPYDER II Computer-to-Screen System

- Technology: Phase-change inkjet / Solid ink

- Resolution: 600 dpi

- Halftone Capability: 75 lpi @ 600 dpi

- Imaging Speed: Approximately 2.4 sq ft/min (13 sq m/h) @ 600 dpi

- Accuracy: .001” from screen to screen

- Power Requirements: 120v/220v 50-60 HZ 15 amp

- Compressed Air: Required

- Network: Ethernet

- Operating Temperature: 50°F to 86°F / 10°C to 30°C

- Operating Humidity: 35% to 75% non-condensing

- Ink Type: Solid block/Water dispersible photo resist mask

- Dimensions:

- SPYDER 30 – 32” x 49” x 61” (79 cm x 124 cm x 155 cm) | Weight: 300 lbs (136 kg)

- SPYDER 52 – 32” x 80” x 61” (79 cm x 203 cm x 155 cm) | Weight: 340 lbs (150 kg)

RIP Specifications

- RIP Type: RTI Harlequin RIP

- Platform: PC

- Screening: AM and FM (stochastic) screening available

- Input File Formats: Postscript III, PDF, EPS, TIFF

- RIP Options: Auto Trapping, Color Management/Proofing, Hybrid Screening

V-LUX

The unique vertical design of the V-LUX Exposure unit allows for simple and easy loading and unloading of a screen, using integrated rails to maintain the proper exposure distance from the LED light source. The unit is built with computer-to-screen in mind and, when combined with EXILE’s SPYDER system, ensures high-quality results. Just insert the screen, press a button (or use automated mode), and your screen is exposed with the correct spectrum of UV light.

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Benefits

- Designed for Computer-to-Screen

- Lamp Life of 50,000 Hours or More

- Optimized UV-LEDs for Low Energy Consumption

- LCD Touch Screen for Fully Automatic Manual Operation

Equipment Specifications

- Power Requirements: Auto-Switching 110 VAC/220;

- VAC 50/60 Hz, 650W Max; VAC 50/60 Hz, 1300W Max

- Operating Temperature: 50°F – 95°F (10°C – 35°C)

- Storage Temperature: 40°F – 122°F (5°C – 50°C)

- Operating Humidity: 35% – 75% Non-Condensing

- Operating Mode: Auto/Manual On/Off

- Exposure Setup: 4.3” Color Resistive Touch LCD

- Dimensions:

- V-LUX – 35.25” x 16” x 51” (895 mm x 406 mm x 1295 mm) | Weight: 100 lbs (45.36 kg)

- V-LUX XL – 62” x 18” x 64” (1574 mm x 457 mm x 1625 mm) | Weight: 230 lbs (104.32 kg)

RIP Specifications

- Outside Dimensions: 35.25” x 16” x 51”/62” x 18” x 64”

- (including door, fan (895 x 406 x 1295 mm)/(1574 x 457 x 1625 mm), cover, and casters)

- Operating Dimensions: 33.5 +2” (900 mm) for fan, 48” x 60” (1219 x 1524 mm) for fan spacing and max screen width (H and D screen width can be the same)

- Max Screen Size: 30” x 40” (760 x 1016 mm)/52” x 60” (1321 x 1524 mm)

- Weight: 100 lbs (45.36 kg)/230 lbs (104.32 kg)

SCREENMAKER

SCREENMAKER CTS produces high-quality stencils in minutes with automatic digital image registration built in.

After imaging, the screen is ready for immediate exposure without the need for a glass or vacuum. Pinholing and undercutting are completely eliminated, so small halftone highlight dots and shadow details are accurately reproduced.

The SCREENMAKER CTS is powered by CADLink’s SCREENMAKER RIP for imaging color separations quickly and easily from any Mac or Windows graphics application. It also includes a standalone Windows printing utility for print queue management, printer setup, and maintenance (ink level monitoring, nozzle checks, head cleaning, head alignment, etc.).

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Benefits

- Metal Body Industrial Design

- Robust Y-Axis for Greater Precision

- Native Support for 1-Bit Tiff Workflow

- Micro-Weaving Technology

- Increases Print Speed

- Bi-Directional Printing for Faster Print Modes

- User-Friendly Print Utility Software

Equipment Specifications

- Model: SCREENMAKER Computer-to-Screen System

- Printhead: Thermal Drop on Demand Inkjet (1-4 offset heads – software selectable)

- Resolution: 600×1200, 1200×1200, & 1200×2400 dpi for max screen rulings of 65 dpi

- Max Media Size: 40” (1050 mm) high x 26” (600 mm) wide

- Max Image Size: 29” (735 mm) high x 20” (508 mm) wide

- Imaging Speed: FAST = 2.5 min per sq ft, NORMAL = 5 min per sq ft, HQ = 8 min per sq ft

- Interface: USB (via PC Windows)

- Voltage: AC 120/220V Auto-sensing

- Environment: 40-70% relative humidity

- Weight: 110 lbs (50kg)

- Dimensions: 48” x 40” x 16.5” (1250 mm x 1020 mm x 420 mm)

Ink Specifications

- Ink Type: Pigment-Based Aqueous UV-Black Ink

- UV Blocking Capability: Enhanced UV Resistance – Black Density in Excess of 3.5 UV

- Ink Characteristics: Water Soluble and Non-Hazardous

Expose

The EXPOSE is a UV-LED screen exposure system designed to complement EXILE’s SCREENMAKER computer-to-screen system. Its compact design serves as a high-quality exposure unit and a sturdy tabletop for your new CTS equipment. When a screen is finished printing, simply slide it into the enclosed tray, select one of 10 timed presets, and your screen will be exposed to powerful UV-LEDs. The EXPOSE works with any screen emulsion, supplying quick and even curing of the emulsion.

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Benefits

- Built to Seamlessly Work with CTS Systems

- Space-Saving Tabletop Design

- Powerful and Reliable UV-LEDs for Fast and Accurate Exposure

- Supports Frame Sizes up to 27” x 37”

Equipment Specifications

- Model: EXPOSE CTS UV-LED Screen Exposure System

- Max Screen Size: 27 in x 37 in (70 cm x 90 cm)

- Exposure System: UV-LED Bulbs – Full Array, 9 Bulbs x 11 Rows, 390 nm Wavelength

- Power: 1.15 KW, AC 220-230 V, 110 V

- Environment: 50-70% Relative Humidity

- Temperature: 68°F – 86° F (20°C – 30°C)

- Weight: 242 lbs (110 kg)

- Dimensions: 37.6 in x 51.2 in x 41.4 in (955 mm x 1300 mm x 1050 mm)

RIP Specifications

- IPure Photopolymer: 30 seconds to 1 minute

- Dual Cure: 2 to 3 minutes

- Diazo: 3 to 5 minutes

*Speeds will vary depending on mesh counts and coating method.